Why Choose Us

WUXI WEIFU INTERNATIONAL TRADE Co., Ltd. is a company with over 20 years’ experience in machining tool equipment industry.

The Intelligent Equipment Business Division provides Superior non-standard tooling, cutting tools, as well as integrated solutions for non-standard automation, intelligent equipment, and industrial internet, which can meet various production scenarios such as machining, precise measurement, honing and milling.

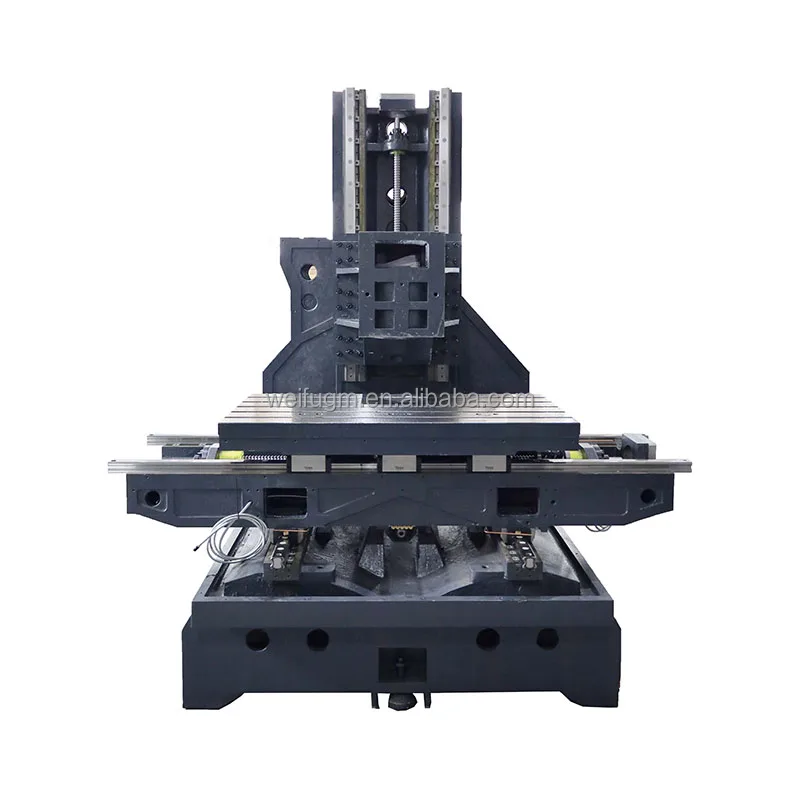

Our main products include Vertical Machining Centers, Horizontal Machining Centers, Gantry Machining Centers, CNC grinder, CNC Lathes and related components. We warmly welcome domestic and foreign customers to establish cooperation with us and jointly create a bright future.